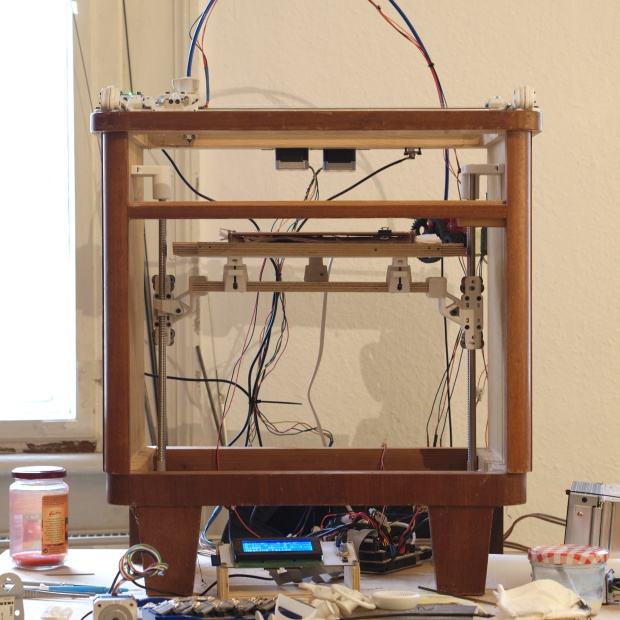

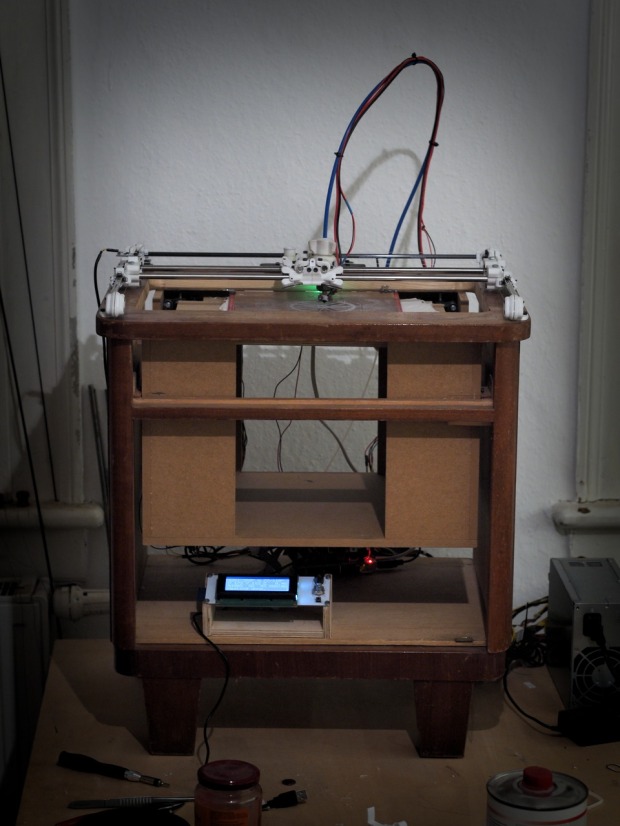

Good news, everyone! Schorsch is now living and working at OIST, Okinawa, Japan. Don’t worry about his wooden body, the Lab he’s in has a nice dry atmosphere and he shares it with a lot of far more expensive stuff. So far he’s doing a good job, but the fancy new place with ocean view has a steady cold breeze from the AC above so i will have to do something about that.

He survived the 14hrs+ in a plane with minor injuries on Z. Luckily the parts that broke were meant to break in case of failure and i am quite proud that there were no further problems due to the loose, rocking Z-axis. X and Y arrived fully working, even the lines haven’t jumped off any bearing. Remember to fix EVERY part that can move when you put your Printer on an international trip!

It works so well…

It works so well…

Despite working hinges (!)

Despite working hinges (!)

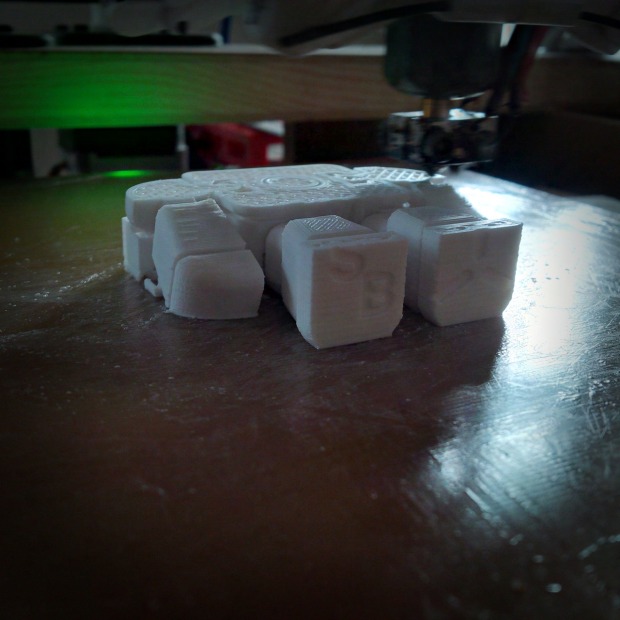

Sometimes you just want to print something to see if the changes you made on your maschine made it better or worse. A few days ago i installed new step-sticks for X and Y, the ones with 1/32 microstepping. Although the stepps/mm doubled, my Ramps has no problems driving SXY with 400mm/s on rapid-moves. The sound is a bit smoother but there is still room for improvement…

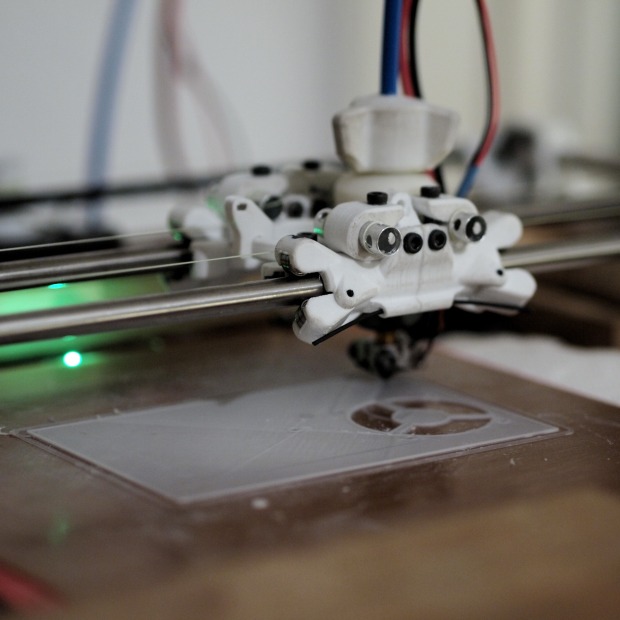

Sometimes you just want to print something to see if the changes you made on your maschine made it better or worse. A few days ago i installed new step-sticks for X and Y, the ones with 1/32 microstepping. Although the stepps/mm doubled, my Ramps has no problems driving SXY with 400mm/s on rapid-moves. The sound is a bit smoother but there is still room for improvement… Schorsch’s new Z-bearings will look kind of like X and Y. But in stead of the 8mm Rods X and Y use i want to use 10mm to reduce shaking. The BBs are 13mm in diameter because there is no need to make it as small as X and Y. Maybe i should support the rods… and redesign the shown part… and rethink all other related parts… meh.

Schorsch’s new Z-bearings will look kind of like X and Y. But in stead of the 8mm Rods X and Y use i want to use 10mm to reduce shaking. The BBs are 13mm in diameter because there is no need to make it as small as X and Y. Maybe i should support the rods… and redesign the shown part… and rethink all other related parts… meh.

You must be logged in to post a comment.